Specialized

Flexocraft Finds Freight Freedom with Wilson

Overview

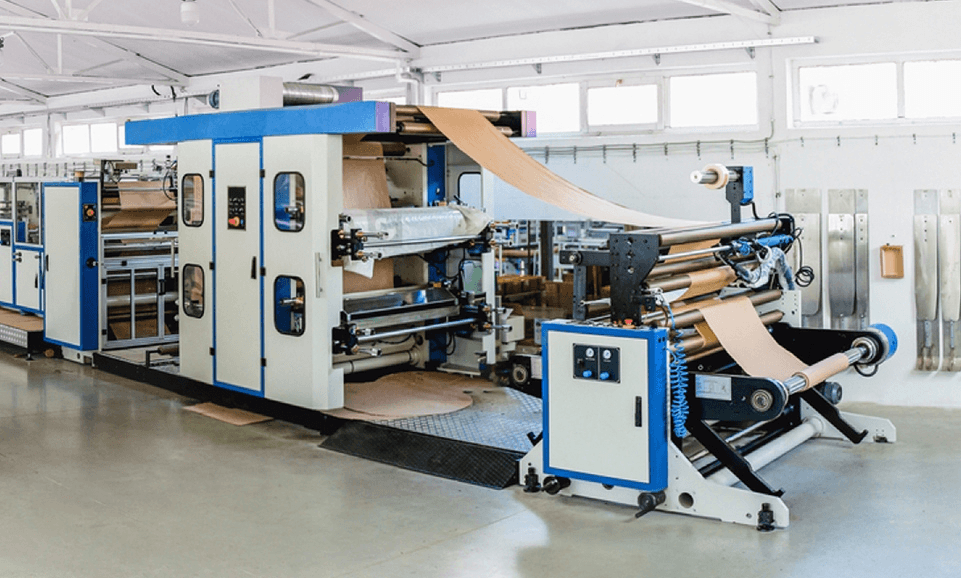

For Flexocraft, packaging isn’t just a product—it’s a craft built across generations. With roots that trace back to 1916, their team has spent decades perfecting the precision, reliability, and style that retail packagers depend on. But as their operation expanded across coasts and across oceans, the logistics behind that craftsmanship grew more complex—fast.

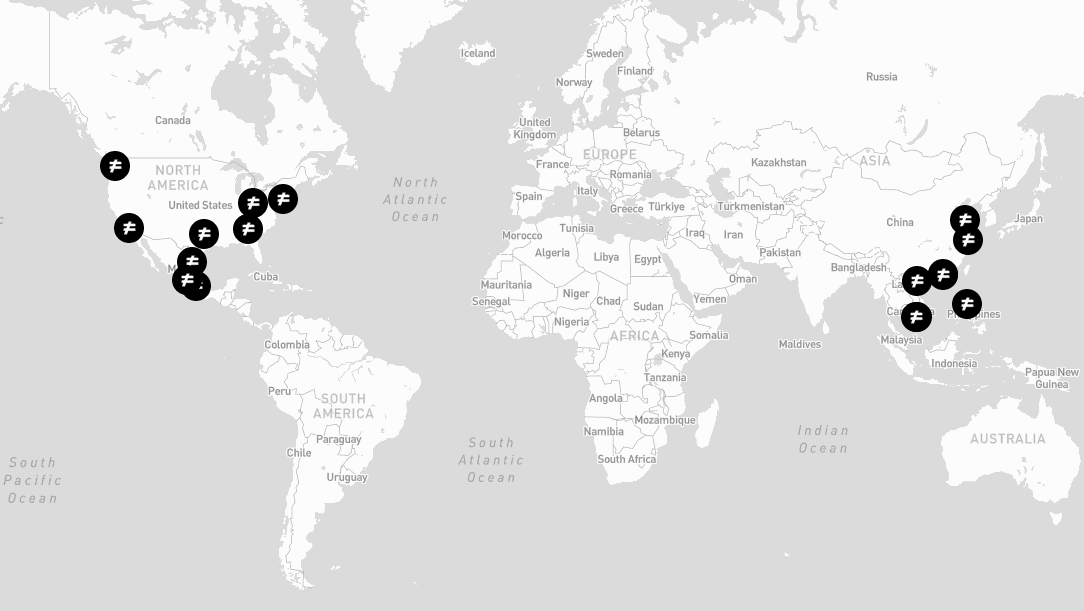

Wilson, our AI logistics coordinator, was brought in to operate as a true teammate: handling inbound and outbound freight, coordinating warehouses, logging into portals, auditing shipments, and keeping teams aligned across time zones. Today, Wilson helps Flexocraft move imported goods from overseas through Los Angeles and New Jersey, then intelligently distributes inventory across the U.S. via parcel, LTL, and truckload—without losing visibility, control, or speed.

Flexocraft’s business runs on timing. Imports arrive with shifting ETAs, warehouse constraints change daily, and orders must be fulfilled with consistency—even when the data is scattered across emails, portals, sales orders, and systems that don’t speak the same language. And because multiple internal teams touch different parts of the operation worldwide, Flexocraft needed something more than a dashboard. They needed a centralized source of truth that could keep up with the real world.

That’s where Wilson fits.

A single Source of Truth

Across import, outbound, inbound, and warehousing, Wilson works directly inside Flexocraft’s existing workflows—logging into carrier and warehouse portals, pulling updates, reconciling what changed, and making sure nothing gets missed. Instead of information living in scattered inboxes, spreadsheets, and “tribal knowledge,” Wilson structures unstructured updates (emails, sales orders, confirmations, exceptions) into clean, trackable operational data.

Every day, Wilson provides Flexocraft with clear reporting on status, efficiency, and risk—surfacing issues early, escalating problems when something looks off, and giving teams confidence that what they’re seeing is accurate and improving customer experience. He doesn’t just pass along updates—he audits them.

The result is a logistics operation where everyone—across offices, teams, and regions—can operate from the same reality.

Smarter Carrier Decisions

As Flexocraft scaled, carrier selection became a bigger lever. Cost mattered, but reliability mattered just as much—especially with more lanes, more shipment types, and more customer expectations on the line.

Wilson continuously helps optimize carrier selection by balancing performance and cost, expanding Flexocraft’s carrier network, and giving the team more options and autonomy. With more carriers comes more complexity—but Wilson stays on top of it, tracking performance and making it easier for Flexocraft to make confident decisions without slowing down operations.

And when Flexocraft has better carrier coverage and better reliability, their customers feel it too: more consistent delivery, fewer surprises, and a better buying experience backed by logistics that actually keep pace.

Built to coordinate the entire operation

Wilson isn’t limited to a single department or a single “owner.” At Flexocraft, he supports multiple internal teams across the world—each handling different parts of the operation—while keeping everything centralized. That means fewer handoff failures, fewer “who has the latest update?” moments, and fewer delays caused by information gaps.

Wilson makes the operation easier to run because he makes it easier to trust the data.

What’s Next

Flexocraft and Cartage are building toward the next evolution of Wilson’s role: extending operational clarity beyond internal teams and directly to Flexocraft’s customers.

The path forward includes:

A customer portal where Wilson proactively updates customers on their orders

Custom API connections to warehouse software to deepen automation and visibility

With Wilson, Flexocraft isn’t just moving freight. They’re building a modern logistics foundation that matches the quality of the product they’ve crafted for generations.