Commodities

From CSV to Covered Loads: Musser Biomass + Wilson

Overview

Musser Biomass & Wood Products turns green hardwood chips and sawdust into premium dry wood products for customers across the U.S. From their Rural Retreat, VA facility, they ship frequent truckloads across a wide mix of lanes.

Before Wilson stepped in, their logistics manager was:

Manually sending out 8 quotes per shipment

Handling 12+ shipments every day

Spending ~30 minutes per load just to build and send quote requests

That’s 6+ hours per day spent on repetitive email blasting and spreadsheet wrangling — time that wasn’t spent on strategy, carrier relationships, or exception handling.

To keep up without expanding their back office, Musser brought on Wilson, Cartage’s AI logistics coordinator, to live inside their existing email and CSV workflow and turn raw order data into covered loads—so the team can stay focused on production and quality.

How Wilson Was Implemented

Musser initially brought in Wilson for basic shipment entry. But as volumes and lanes grew, their reliance on Wilson expanded too, into a fully integrated CSV-to-truck workflow.

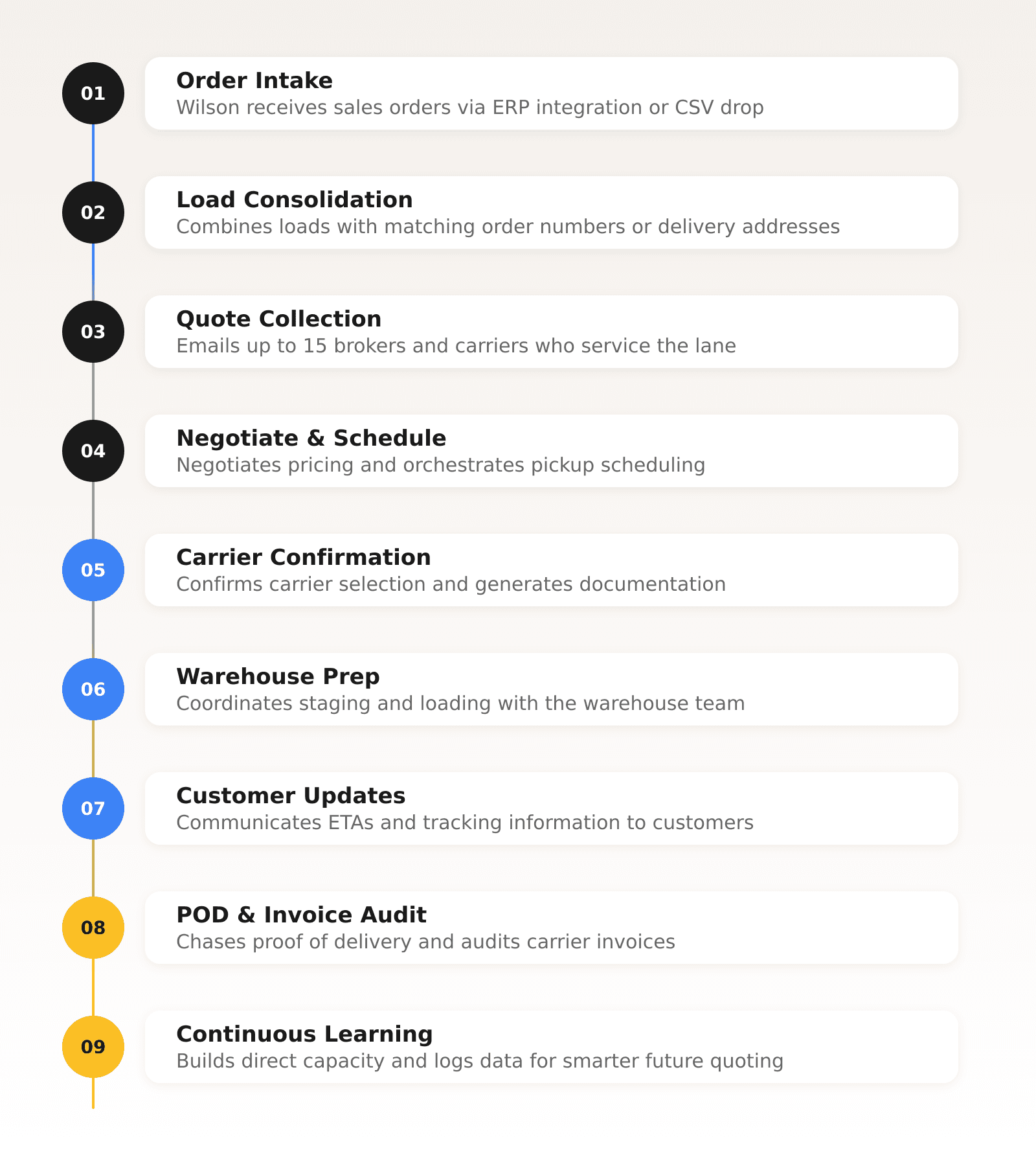

Today, Wilson receives sales orders via ERP or CSV and handles the heavy lifting:

The net effect: review and approve when needed, and let Wilson orchestrate the quoting, documenting, and coordination behind the scenes.

Impact

With Wilson, Musser has turned a manual, CSV-driven process into a repeatable, semi-automated workflow. The team still controls carrier selection and approvals, but they spend far less time wrestling with spreadsheets and email threads—and more time continuing their core mission: redefining what dry wood fiber can be.